A riser plays a crucial role in the design and function of various systems, from building infrastructure to offshore engineering. The primary function of a riser is to transport fluids, gases, or materials vertically within a structure or system, ensuring the efficient flow of resources between levels.

Whether you’re involved in building construction, plumbing systems, or offshore oil and gas operations, understanding the primary function of a riser will give you insight into its importance and its applications.

The term “riser” can refer to several types of vertical components used across various industries. Broadly speaking, a riser is any vertical structure or system that facilitates the movement of fluids, gases, or materials. These systems are found in everything from residential buildings to offshore drilling rigs. Risers help maintain the flow of essential resources by connecting different levels or sections of a structure or system.

To better understand what exactly a riser is, let’s break it down based on its most common applications.

Definition of a Riser

A riser is a vertical conduit or pipeline used in different engineering applications, such as:

- In buildings: A riser is typically a vertical pipe or duct used to carry water, gas, electricity, or air to various floors in multi-story structures. This could be in the form of plumbing pipes, HVAC systems, or electrical conduits.

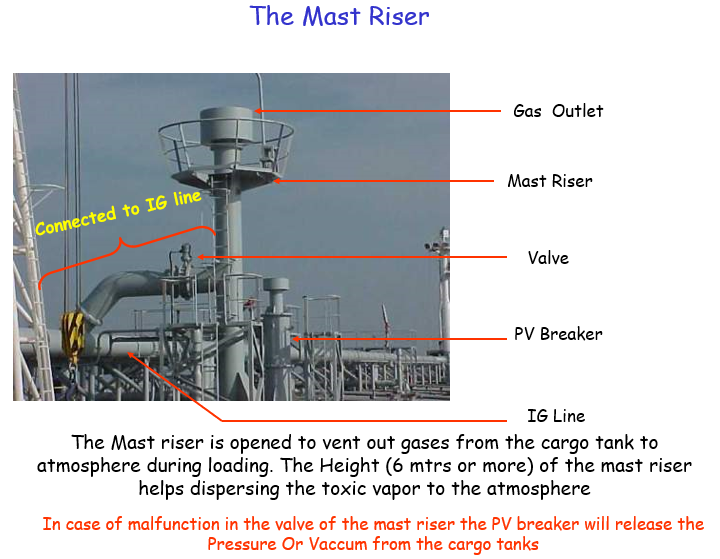

- In offshore engineering: A riser is a pipe that connects an underwater oil or gas well to the surface platform, allowing the transfer of hydrocarbons or other fluids. These types of risers are designed to withstand extreme conditions in deepwater environments.

- In plumbing: A riser pipe is used to carry water or sewage from one floor to another, often seen in apartment buildings or high-rise residential complexes.

In all cases, risers are designed to transport something vertically, which is why they are an essential part of various systems across different sectors.

Where Do You Find Risers?

Risers are found in several types of systems and industries:

- In Construction: In buildings, risers are used to transport water, gas, or electrical systems from the ground floor to the upper floors. Plumbing risers carry water or sewage, while HVAC risers allow the movement of air conditioning and ventilation ducts. Electrical risers ensure the distribution of power through the building.

- In Offshore Oil and Gas: Offshore risers are used to carry oil and gas from deep-sea wells to the surface for processing. These risers play an essential role in subsea production systems, making it possible to access and transport valuable resources from beneath the ocean floor to production platforms.

- In Fire Systems: In tall buildings, fire risers carry water from the main supply to the fire sprinklers or fire hydrants at various levels of the building, ensuring proper water distribution in case of a fire emergency.

Risers are truly versatile and can be found in all sorts of infrastructure projects, whether above or below the ground.

Primary Function of a Riser in Different Industries

Risers serve different functions depending on the industry they’re used in, but their primary role across all these sectors is to facilitate the efficient transport of fluids, gases, or materials vertically. The functionality may vary slightly from one application to another, but the core purpose remains the same: risers help move vital resources to higher or lower levels, ensuring systems operate smoothly.

The Role of Risers in Building Construction

In building construction, risers are critical to the smooth operation of vertical systems like plumbing, electrical wiring, and HVAC (heating, ventilation, and air conditioning). Here, risers are primarily used to provide pathways for water, gas, electricity, and air to be distributed across multiple floors in high-rise buildings or multi-story complexes.

- Plumbing Risers: In residential or commercial buildings, risers are used to carry water or waste pipes vertically. These pipes ensure that water reaches higher floors for bathroom fixtures, kitchens, and other water-based needs, while also carrying waste down to the building’s sewage system.

- Electrical Risers: Electrical risers carry power cables vertically from the main distribution board to different levels of the building. These risers ensure a continuous flow of electricity, enabling lighting, heating, and other electrical needs in a building.

- HVAC Risers: Air conditioning or ventilation ducts are also vertical systems known as risers in buildings. They distribute heated or cooled air to various levels, ensuring proper airflow and temperature control in the building.

In these applications, risers are essential for efficient building operation. Without them, systems like plumbing and electrical wiring would not function correctly, and daily activities would be disrupted.

The Function of Risers in Plumbing Systems

In plumbing systems, risers play a critical role in ensuring the proper distribution of water or gas throughout a building. They allow water to flow from one level to another in multi-story buildings, such as apartment complexes or office buildings, and are essential for keeping water pressure consistent across the floors.

- Water Supply Risers: Water risers connect the building’s main water supply to individual fixtures such as sinks, showers, and toilets on different floors. They are designed to handle the pressure required to move water vertically and ensure that each fixture gets an adequate supply of water.

- Gas Risers: In buildings with natural gas systems, gas risers allow the transport of natural gas from the main supply line to various floors. These risers ensure a continuous flow of gas to appliances like stoves, water heaters, and heating systems.

Without well-designed plumbing risers, water or gas could not be distributed effectively, which would lead to inefficiencies or even dangerous situations like water hammer or gas leaks.

Offshore Engineering: Function of a Riser in Oil and Gas

In the world of offshore engineering, risers are essential for the transportation of hydrocarbons (such as oil and gas) from subsea wells to surface platforms. These risers are often quite different from those used in buildings, as they are subjected to much more extreme conditions.

Offshore risers can be divided into two major categories: flexible risers and rigid risers. These systems connect oil and gas platforms to wells on the seabed, ensuring that resources are transported safely and efficiently.

- Flexible Risers: Flexible risers are designed to adapt to dynamic underwater conditions. They are used in deepwater and ultra-deepwater environments, where constant movement from waves and currents may affect the platform. These risers use flexible materials like rubber and steel, enabling them to bend and flex without breaking.

- Rigid Risers: Unlike flexible risers, rigid risers are built using steel pipes and are used in more stable, shallow-water environments. They are designed to withstand external pressure and resist bending.

The primary function of these risers is to provide a secure pathway for the transportation of oil, gas, and other fluids from the seabed to offshore production facilities, often at great depths. These risers are designed to withstand extreme temperatures, high pressures, and corrosive seawater, making them a vital component in offshore oil and gas extraction.

Why Is a Riser Important in Engineering and Construction?

Risers are often overlooked as simple pipes or conduits, but they are integral to the function and efficiency of a building or infrastructure system. Understanding the importance of risers in engineering and construction can help highlight their role in ensuring the smooth operation of essential systems. The primary function of a riser is to support the vertical movement of fluids, gases, or materials, but their benefits go beyond this simple task.

Facilitating Efficient Movement of Fluids and Gases

One of the most critical aspects of risers is their ability to facilitate the efficient movement of fluids and gases through a structure. In buildings, this means ensuring that water, natural gas, and air reach the necessary areas without loss of pressure or flow. Without risers, fluid distribution systems would be inefficient, potentially leading to disruptions in service, low water pressure, or gas leaks.

- Water Distribution: In plumbing systems, risers are designed to move water from the ground floor to upper levels without reducing pressure. In high-rise buildings, especially, the hydrostatic pressure (pressure exerted by water at rest) can be an issue, so risers help to counteract the potential loss of pressure that occurs when moving water upwards.

- Gas Distribution: Similarly, gas risers ensure a consistent flow of natural gas or LPG to the various levels of a building. These risers are designed to prevent leaks or blockages, which could result in dangerous situations, such as gas build-up or insufficient heating.

- HVAC Systems: Risers in HVAC systems enable the distribution of air throughout the building. Whether it’s cool air in the summer or warm air in the winter, these systems rely on risers to move air efficiently from the central system to each floor or room.

Risers are, therefore, essential to maintaining the integrity of these systems, ensuring reliability and safety for all building occupants.

Supporting Vertical Infrastructure

Another crucial role of risers is their ability to support vertical infrastructure within a building or structure. In high-rise buildings, the systems that rely on vertical pathways—such as water pipes, gas lines, electrical cables, and ducts—need to be organized in a way that supports their function while maintaining ease of access for repairs and maintenance.

- Vertical Transportation: Risers help organize different infrastructure elements into clear vertical pathways. This can make construction and maintenance much easier. Rather than running pipes, cables, or ducts through walls and floors without structure, risers provide a centralized location for these elements. This structure helps to reduce the need for disruptive renovations or repairs later on.

- Space Efficiency: In high-rise buildings, space is at a premium. Risers help optimize the use of space by consolidating essential systems into dedicated vertical channels, ensuring that other areas of the building can be used for living, working, or recreational purposes. This careful design maximizes floor area and minimizes construction waste.

In essence, risers are the backbone of vertical infrastructure in any building, allowing for efficient and organized distribution of vital resources and systems.

Reducing Risk and Ensuring Safety

Risers are not only about functionality—they also play a significant role in safety. By ensuring that pipes, cables, and ducts are properly contained in riser shafts, they help reduce the risks associated with leaks, fire hazards, and flooding.

- Fire Prevention: In many buildings, fire risers are designed to ensure that water reaches every floor during an emergency. These risers are critical in ensuring the building’s fire suppression system is operational, providing firefighters with an efficient water supply to fight fires.

- Preventing Gas Leaks: Gas risers are specially designed to prevent leaks and maintain a consistent flow of gas. Since gas leaks are a significant hazard, risers help ensure that there is no gas build-up in a building, minimizing the risk of an explosion or suffocation.

By providing controlled pathways for potentially hazardous materials, risers help improve the overall safety of buildings and industrial systems.

Types of Risers

Risers come in various forms, depending on their application and the environment they are designed for. Understanding the different types of risers and how they function is crucial to determining which type is most suitable for a specific project.

Vertical Risers

Vertical risers are perhaps the most common and recognizable type of riser, especially in building construction and plumbing systems. These risers are designed to carry fluids, gases, or electrical cables vertically between different floors of a building.

- Water and Gas Distribution: Vertical risers in plumbing systems are typically large pipes that carry water or gas to different levels of a building. These risers are designed to handle high pressure, particularly in tall buildings, to ensure a consistent supply of water and gas.

- Electrical and HVAC Systems: Vertical risers also serve as conduits for electrical wiring and air ducts. By consolidating these essential systems into vertical shafts, risers help organize the building’s infrastructure and maintain safety standards.

In buildings with multiple stories, these risers are crucial for moving essential resources between floors, ensuring the smooth operation of plumbing, electrical, and HVAC systems.

Flexible Risers

Flexible risers are used predominantly in offshore engineering and subsea production systems, where dynamic conditions such as wave movement and pressure changes in the deep sea make rigid pipes impractical. These risers are designed to withstand extreme conditions, including underwater currents, pressure fluctuations, and high temperatures.

- Offshore Oil and Gas: Flexible risers are commonly used to transport oil, gas, and water from the ocean floor to the surface platforms. They are built using a combination of steel and polymer materials, allowing them to bend and flex while maintaining their structural integrity.

- Deepwater Conditions: These risers are ideal for deepwater and ultra-deepwater drilling operations because they can adjust to movement and avoid breaking or damaging the pipeline. Their flexibility is key to surviving the dynamic underwater environment, where strong currents and shifting seabeds can stress rigid systems.

In the context of offshore platforms, flexible risers are essential for ensuring the safe and reliable transport of critical resources from deep-sea wells to production platforms.

Rigid Risers

Unlike flexible risers, rigid risers are constructed from stiff materials like steel and are designed to handle conditions where movement is less of a concern, such as in shallow-water offshore applications. Rigid risers are commonly used in situations where the riser will remain in a fixed position.

- Offshore Oil and Gas: Rigid risers are often used in shallow waters or fixed platforms where they connect subsea wells to surface production facilities. These risers are more resistant to bending and are ideal for stable environments.

- High-Pressure and High-Temperature Applications: Rigid risers are built to withstand high pressures and extreme temperatures, making them suitable for applications where the flow rate of oil and gas needs to be maintained at high levels.

Rigid risers are an excellent choice when stability and pressure resistance are the primary concerns, especially in fixed offshore platforms where flexibility isn’t necessary.

Common Materials Used in Riser Construction

The material used to construct a riser is essential for its performance and longevity. Risers are subjected to varying pressures, temperatures, and environmental conditions, which means choosing the right material is crucial for ensuring they operate efficiently and safely.

Materials for Plumbing Risers

In building construction, the materials used for plumbing risers depend on the type of system, pressure requirements, and cost considerations. Common materials include:

- Copper: Known for its durability, corrosion resistance, and high heat conductivity, copper is often used in water risers in buildings. Copper risers are commonly found in residential and commercial plumbing systems due to their ability to resist corrosion from water.

- PVC (Polyvinyl Chloride): PVC is a cost-effective and lightweight material commonly used in low-pressure plumbing systems. It’s often used for wastewater or sewage risers, as it’s resistant to corrosion and easy to work with.

- PEX (Cross-linked Polyethylene): PEX is a flexible and corrosion-resistant material that is often used in modern plumbing systems. It’s commonly found in water risers due to its flexibility and ease of installation.

Each material is chosen based on its cost-effectiveness, longevity, and ability to meet specific pressure or flow requirements.

Materials for Offshore Risers

For offshore applications, the materials used to construct risers need to be able to withstand extreme pressure, corrosion, and other harsh environmental factors. Some of the materials commonly used in offshore risers include:

- Steel: Steel is a preferred material for rigid offshore risers due to its strength and resistance to corrosion when coated with appropriate protective layers. It is highly resistant to pressure and temperature extremes, making it suitable for deep-sea environments.

- Composite Materials: Fiberglass and other composite materials are increasingly being used for flexible risers in offshore applications. These materials are lighter than steel and offer excellent corrosion resistance, making them ideal for underwater environments.

- Thermoplastic Materials: Some flexible risers are made using advanced thermoplastic materials like polyurethane and polyamide, which offer flexibility while being resistant to chemicals and extreme conditions.

The choice of material depends largely on the operating environment, pressure and temperature conditions, and cost considerations for the specific riser application.